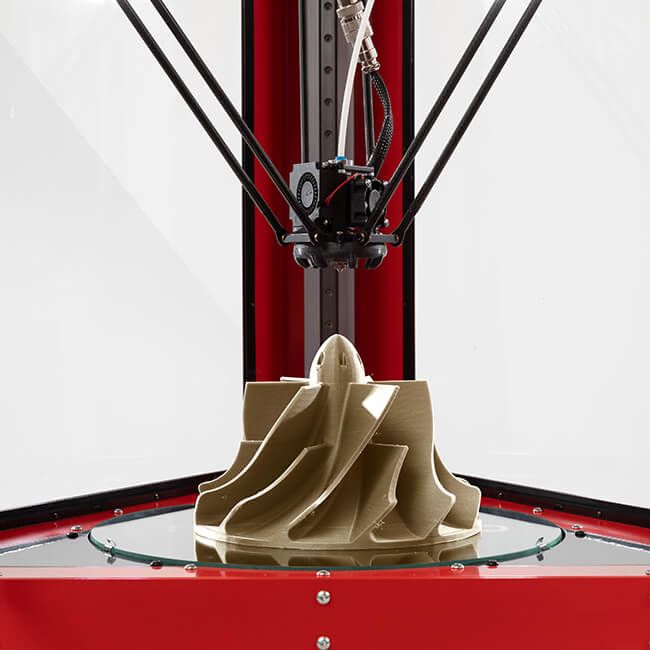

The NX850 PRO in our PRO series is the best high temperature 3D printer in the market. With a height of just 114 cm, it still fits on your desk, but you can print high-temperature polymers like PEEK up to 400 mm (15.7″) in height and 280 mm (11″) in diameter.

The NX850 PRO;

Heated Chamber

The temperature inside the NX850 PRO can be easily controlled with an innovative heated chamber. Thermal management helps reduce warping by minimizing premature cooling from open air. The heated chamber allows the user to set the temperature to the required level, up to 65 degrees Celsius.

Generous Build

Volume Featuring a spacious build volume of 280mm x 400mm (diameter x height), this versatile 3D printer is exceptionally valuable for prototyping and small batch production.

High Temperature Capability

The high-temperature nozzle reaches up to 450°C, and the build plate can heat up to 175°C. The NX850 PRO empowers you to craft prototypes using premium materials like Carbon PEEK, PEEKQ, and ULTEM. Moreover, conventional materials such as PLA and PETG remain fully printable.

NEXUM is dedicated to fostering innovation in every conceivable way. We don’t settle for good; our aim is to achieve greatness or perfection. While the latter is a challenging goal with our relentless pursuit of continuous improvement, we believe we’re doing an excellent job. We harness our passion to create an exceptional product lineup for PEEK 3D printing, which includes the NX850 PRO.

NX850 PRO specifications

| Machine Properties | |

| Build width | 280 mm diameter (11″) |

| Build height | 400 mm (15.7″) |

| Travelspeed | 450 mm/s |

| XYZ resolution | 10 micron |

| Layer resolution | |

| 0.4 mm nozzle | 300 – 10 micron |

| 0.6 mm nozzle | 450 – 10 micron |

| 0.8 mm nozzle | 600 – 10 micron |

| 1.0 mm nozzle | 800 – 50 micron |

| Physical dimensions | |

| Dimensions | 550 mm x 476 mm x 1140 mm |

| Net. weight | 30 kg |

| Heated build plate | |

| Build plate temperature | up to 175 °C (347 ºF) |

| Build plate levelling | Automatic |

| Heat up time (up to 60 °C / 140 ºF) | < 2 min |

| Print head | |

| Nozzle temperature | up to 450 °C (842 ºF) |

| Nozzle heat up time | < 90 sec |

| Max. extrusion volume | up to 40 mm3/s |

| Heated chamber | |

| Heating | Actively heated chamber |

| Heat up time (up to 60 °C / 140 ºF) | < 7 min |

| Temperature | up to 80 °C (176 ºF) |

| Installation | Plug and play |

Unlocking Boundless Possibilities with High-Temperature 3D Printing

High-temperature 3D printing is revolutionizing the world of additive manufacturing. This cutting-edge technology enables the creation of parts and prototypes using advanced materials that can withstand extreme heat and stress. From aerospace components to medical devices, high-temperature 3D printing opens up a world of possibilities.

The Advantages of High-Temperature 3D Printing

-

Diverse Material Options: High-temperature 3D printers are compatible with a wide range of advanced materials, including PEEK, ULTEM, and PEI. These materials offer exceptional heat resistance, chemical stability, and mechanical strength.

-

Precision and Complexity: High-temperature 3D printers excel in producing intricate and precise components. Their capability to print complex geometries with precision makes them a preferred choice for industries demanding intricate, customized parts.

-

High-Performance End Products: Parts created through high-temperature 3D printing exhibit superior performance characteristics. These parts can endure extreme temperatures, corrosive environments, and mechanical stress, making them ideal for demanding applications.

-

Time and Cost Savings: High-temperature 3D printing streamlines the manufacturing process. It reduces material waste and minimizes the need for costly tooling, leading to significant time and cost savings.

Applications of High-Temperature 3D Printing

-

Aerospace Industry: High-temperature 3D printing is instrumental in crafting lightweight yet robust components for aircraft and spacecraft. These components can withstand the rigors of space travel and high-temperature atmospheric conditions.

-

Medical and Healthcare: Medical professionals use high-temperature 3D printing to create custom implants, prosthetics, and surgical tools. The ability to tailor products to individual patient needs is a game-changer in the healthcare industry.

-

Automotive Sector: High-temperature 3D printing is widely adopted for producing engine components, exhaust systems, and under-the-hood parts that require exceptional heat resistance and durability.

-

Oil and Gas: The oil and gas industry benefits from high-temperature 3D printing for manufacturing components that can endure extreme temperatures and corrosive substances found in drilling and extraction operations.

Choosing the Right High-Temperature 3D Printer

Selecting the right high-temperature 3D printer is crucial for achieving your specific manufacturing goals. Consider factors such as build volume, nozzle temperature, and material compatibility when making your choice.

In Conclusion

High-temperature 3D printing is at the forefront of advanced manufacturing, offering versatile solutions for industries seeking top-quality, durable components. By harnessing the power of this technology, businesses can unlock new opportunities, streamline production, and create products that perform reliably under the harshest conditions.

Explore the potential of high-temperature 3D printing to take your manufacturing capabilities to the next level. Discover how this innovative technology can elevate your products and drive your business forward.